Surface Treatment and Assembly

Barrel Tumbling

Vibratory finishing is an innovative method for rounding and smoothing the edges of components made from various materials, such as steel, cast iron, aluminium, brass, plastic, and ceramics. This process involves placing the parts in a vibratory barrel, where they rotate in an abrasive medium and appropriate chemical solutions, including a mixture that provides preliminary corrosion protection. Owing to precisely selected parameters, it is possible to quickly and effectively achieve the desired smoothness and surface quality, without the risk of damaging or deforming the components.

Our Machining Capabilities

The vibratory barrel available at Bukpol, due to its size, allows for the simultaneous processing of many components, saving both time and costs. We offer processing with two types of shapes, depending on the material used for the components:

- Resin Shapes – Made from composite resins and abrasives, these are less aggressive and are ideal for processing components made from aluminium, brass, or plastics. The shapes available in our company are of medium grinding class, making them perfect for delicate processing without the risk of damage.

- Ceramic Shapes – Made from a harder ceramic material, these are more aggressive and are perfect for processing steel, cast iron, and other hard metals. The shapes available at our company are in the medium polishing-grinding class, making them excellent for deburring and polishing surfaces, preparing them for the application of various paint and galvanic coatings.

Capacity: 800 litres. Maximum batch weight: 1200 kg. Component size range: from 10 mm to 500 mm.

Advantages of Vibratory Finishing in Our Offer

- Wide range of materials – We support a diverse array of projects regardless of the base material, using both resin and ceramic media tailored to specific needs.

- Precision Surface Finishing – Vibratory finishing ensures perfectly rounded edges and smooth surfaces, which is essential for components requiring high aesthetics or preparation for painting and electroplating.

- Damage Protection – The process is controlled and gentle, minimising the risk of mechanical damage or deformation, even for delicate components.

- Reduced Processing Time – Thanks to the large capacity of our vibratory barrel, multiple components can be processed simultaneously, significantly reducing production time and costs.

- Surface Preparation for Further Processing – Vibratory finishing effectively prepares surfaces for the application of paint, electroplated coatings, or other finishing treatments.

Shot Blasting

A surface treatment process that plays a crucial role in the metallurgical industry. It involves the removal of contaminants, rust, paint, or other unwanted substances from metal surfaces by propelling abrasive media—such as steel shot—at high pressure. This method has a wide range of applications, from surface cleaning prior to painting or galvanising, to preparation for subsequent processes such as welding or coating. Shot blasting is highly effective, as it eliminates both visible impurities and subtle surface imperfections that could otherwise compromise the quality or durability of metal components.

Our Surface Preparation Capabilities

We operate advanced shot blasting equipment that helps achieve high-efficiency processing of multiple components simultaneously—resulting in significant time and cost savings. We offer shot blasting services using a wide range of abrasive materials, each carefully selected to match the specific properties and requirements of the components being treated:

- Crushed Steel Grit GH25 – A sharp-edged metallic abrasive with a grain size range of 0.42–1.18 mm. Produced by crushing spherical shot, it delivers high cutting power and aggressiveness. Ideal for cleaning steel and cast iron surfaces, removing rust, mill scale, and old coatings.

- Crushed Grit (Diamant) – With a grain size of 0.8–1.25 mm, this premium sharp-edged abrasive is known for exceptional cutting efficiency and the ability to maintain its sharpness throughout the blasting cycle.

- Chromium-Nickel Shot (CrNi 30) – A stainless, spherical metallic abrasive made from chromium-nickel steel. It offers excellent durability, low dust generation, and resistance to corrosion. It’s the preferred choice for delicate surfaces such as aluminium, stainless steel, and non-ferrous metals, where iron contamination must be avoided.

- Glass Beads – Fine abrasive media with a particle size of 70–110 microns, used for precision blasting applications. Their small size makes them ideal for surface smoothing, matt finishing, or homogenising delicate materials like non-ferrous metals, plastics, or decorative parts.

With a broad selection of abrasive media at our disposal, we are equipped to meet a wide spectrum of client’s requirements—from aggressive surface cleaning to fine surface finishing with exceptional precision.

Advantages of Shot Blasting in Our Offer

- Precision Surface Finishing – Shot blasting effectively removes imperfections while imparting a uniform surface structure and optimal roughness. This is essential for high-adhesion preparation prior to painting, electroplating, or achieving refined visual quality.

- Damage Protection – The process is fully controlled, ensuring that even delicate components are treated without the risk of deformation or mechanical damage.

- Reduced Processing Time – The efficiency of our blasting equipment allows us to process multiple components simultaneously, accelerating production and reducing overall operational costs.

- Ideal Surface Preparation for Subsequent Processes – Shot blasting ensures that surfaces are perfectly prepared for subsequent finishing stages such as painting, galvanising, or other specialised treatments.

Key Features of One of Our Shot Blasting Units:

- Robust Stainless Steel Housing – Ensures long-lasting durability and resistance to corrosion.

- Large, Wide-Opening Doors –easy loading and unloading of oversized components.

- Spacious Blast Chamber – Designed to accommodate high-volume processing.

- Pull-Out Rotary Table – Facilitates the handling and positioning of heavy workpieces.

- High-Power Blast Gun with Pressure Control – Enables precision blasting while protecting delicate parts.

- Boron Carbide Nozzle – Offers exceptional wear resistance and extended service life.

- Manual Water Rinse System – Efficiently removes residues after blasting.

- Manual Air Jet Drying – Speeds up drying time for quicker processing.

- Window Rinse System with Wiper – Maintains clear visibility inside the chamber for safe and accurate operation.

Spray and Ultrasonic Cleaning

To ensure the highest quality of our products and the entire production process, we provide professional cleaning services as an essential part of our comprehensive offering. We utilise advanced cleaning equipment based on two cutting-edge technologies, allowing us to meet a wide range of customer’s requirements:

- Spray Cleaning – An effective and fast method for removing contaminants such as oils, greases, dust, or production residues using a high-pressure water jet combined with carefully selected detergents. This technique is ideal for cleaning larger components where efficiency and short processing time are key priorities.

- Ultrasonic Cleaning – A precision cleaning process using high-frequency sound waves in a liquid bath to dislodge dirt, dust, machining residues, and microscopic impurities. This method reaches deep into hard-to-access areas such as gaps, holes, and internal surfaces, making it perfect for components with complex geometries and stringent cleanliness requirements – especially in the medical, aerospace, and electronics industries.

Advantages of Our Cleaning Services

- Effective Contaminant Removal: Efficiently eliminates contaminants from various surfaces, ensuring high-quality results.

- Safe for Delicate Components: Our cleaning methods are gentle, making them ideal for sensitive parts that require careful handling.

- Preparation for Further Processes: Prepares parts perfectly for subsequent stages such as assembly or coating.

- Commitment to Quality: We use high-quality spray and ultrasonic washers to ensure reliability, precision, and the highest cleanliness standards at every stage of processing.

Component Assembly

Component assembly is a key service in our offering, focused on the precise and reliable joining of parts into complete assemblies according to the client’s individual requirements. This process includes both manual and technology-assisted operations, carried out by our experienced team of specialists and supported by state-of-the-art technical equipment. We provide a comprehensive approach – from component preparation, through marking, to final assembly – allowing us to tackle both simple and complex assembly projects while ensuring the highest quality and timely delivery.

Our Assembly Capabilities

Our versatile equipment allows us to handle a wide range of assembly tasks. We use advanced tools, methods, and technologies to deliver high-quality results. We offer:

- Manual Assembly – Ideal for precise and custom projects where attention to detail is crucial. Our skilled workers assemble components with the utmost care, adhering to specific technical requirements.

- Technologically Assisted Assembly – We use modern assembly stations and supporting devices, such as quality control systems, to accelerate the process and enhance repeatability, especially for larger production batches.

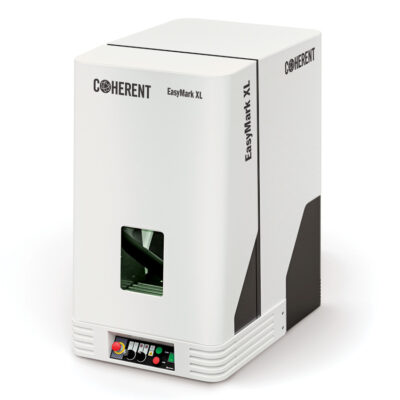

- Laser Marking – With our advanced laser system, we can apply permanent markings such as serial numbers, barcodes, or logos to various materials, from metals to plastics, improving both the functionality and aesthetics of the finished components.

Choose Quality – Choose Bukpol

Our approach to component assembly, supported by 5S and Kaizen methodologies, ensures not only functionality but also aesthetics and complete readiness for further production processes or immediate use. Precision, comprehensive service, flexibility, versatility, and high quality are the pillars of our service, which perfectly complements the other machining processes offered by Bukpol. In this way, we create comprehensive solutions that meet the expectations of clients from various industries.