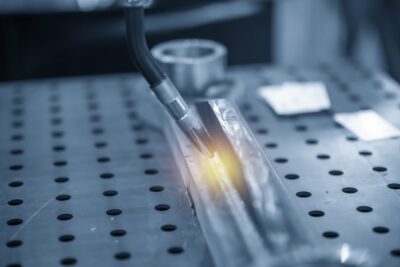

Laser Welding Services

Our company offers professional laser welding services, ensuring the highest precision and quality. Laser welding (derived from the acronym “Light Amplification by Stimulated Emission of Radiation”) is a process in which metals or thermoplastic materials are joined using a focused laser beam. It is the most advanced type of welding, applied in a wide range of industries, from aerospace and medical equipment to jewellery manufacturing.

Coherent Laser Welding Machine Specifications: Max. Output Power: 220W, X-Axis Travel: 13.7″ (34.8 cm), Y-Axis Travel: 7.87″ (20 cm), Z-Axis Travel: 14.5″ (36.8 cm), Maximum Energy: 120J, Wavelength: 1064nm.

Advantages of Laser Welding in Our Offer

- High Precision – The focused laser beam (e.g., 1064 nm) allows for precise welding of even the smallest components.

- Minimal Deformation – The low heat input reduces material distortion.

- Process Speed – The laser’s power ensures fast and efficient material joining.

- Material Versatility – Capable of welding a wide variety of metals and alloys, including those that are difficult to process.

- Cleanliness and Aesthetics – Precise welds with high visual quality, eliminating the need for further processing.

- Application Flexibility – Ideal for both serial production and single, complex components.

Types of Laser Welding in Our Offer

While laser welding does not have as distinct categories as some traditional methods, the variety of techniques – from deep welding to pulsed welding – allows us to tailor the process to the specific requirements of our clients. We offer advanced laser welding solutions, ensuring exceptional precision, weld quality, and work efficiency.

Conduction Welding

- The laser energy is delivered in such a way that heat primarily spreads through conduction.

- It creates wide, shallow welds.

- Application: Thin sheets, components requiring aesthetic welds, e.g. in the automotive industry.

Keyhole Welding

- The high-power laser beam penetrates the material, creating a narrow, deep hole (the so-called “keyhole”) that fills with molten metal.

- It is characterised by deep penetration and a narrow heat-affected zone

- Application: Thicker materials, structures requiring high strength, e.g. in the aerospace industry.

Pulsed Laser Welding

- The laser emits short energy pulses (e.g., max. energy 120J).

- It minimises overheating, making it ideal for delicate or thin materials

- Application: Electronics, jewellery, precision components.

Continuous Wave Welding

- The laser operates in continuous mode, without interruptions, allowing for rapid welding of large surfaces.

- It requires higher power and stability.

- Application: Mass production, e.g. in automotive manufacturing.