CNC Turning

Our company offers comprehensive CNC turning services using state-of-the-art machines.

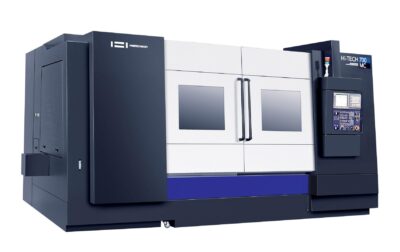

Our machine park consists of modern CNC machines, including:

Okuma Genos (Turning diameter: 300 mm; Maximum length: 350 mm; Equipped with driven tools)

Okuma MULTUS U4000 (turning diameter up to 650 mm, maximum length 1500 mm).

Hwacheon Hi Tech 700MC (turning diameter up to 700 mm, maximum length 2000 mm, with driven tools and hydraulic support).

CNC Turning – Precision and Professionalism in Machining

Bukpol specialises in precision CNC turning, one of the most effective methods of machining. This advanced technology enables chip removal through the rotational movement of the workpiece while the cutting tool performs precise feed movements. With full automation and computer control, we offer CNC turning services of the highest quality.

Advantages of CNC Turning in Our Offer

- Repeatability: The closed coordinate system and advanced control ensure identical components, making us an ideal partner for serial production.

- High Efficiency: Automation eliminates human error, speeding up processes and increasing overall productivity.

- Cost Optimisation: Speed and precision help to reduce the costs, and once a part is designed, it can be produced repeatedly without additional expenses.

- Safety: The automated process minimises the risk of malfunctions and accidents, ensuring stable operation.

- Versatility: We work with a wide range of materials, adapting to the specific needs of our clients.

Our CNC Turning Services

We operate modern CNC lathes controlled by intuitive computer interfaces. The machine controller, connected to an advanced system, enables precise setting of parameters such as rotational speed and tool feed. The process is fully automated – our skilled operators oversee the work, ensuring every detail is taken care of, while the machine performs tasks with unmatched repeatability and accuracy.

How We Execute CNC Turning

The process begins with design. We offer the option of creating vector-based designs using CAD software or manually programming the machine for simpler tasks. For more complex orders, we rely on provided technical drawings and 3D models, which we transform into precise guidelines using CAM software. We establish optimal operating parameters to ensure fast and accurate machining. Our specialists, with their experience and proven procedures, minimise the material waste and reduce the production time.

CNC turning at our company can be applied across a wide range of industries – from machine parts production, through industry, to medical and aerospace sectors. Regardless of the project scale, we offer tailor-made solutions that meet the highest standards.