CNC Milling

We offer comprehensive and precise CNC milling services. This is a machining process where we use 3-axis, 4-axis, and even 5-axis CNC machines with either vertical or horizontal spindles.

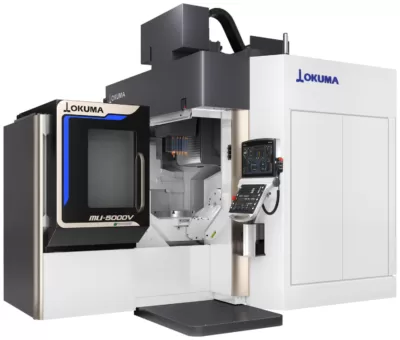

Our machine park consists of modern machining equipment, including:

Okuma Genos M460V-5AX (machining capability: 762 x 460 x 460 mm)

Okuma MA-500HII (machining capability: 700 x 900 mm)

Okuma MU-5000V (machining capability: 800 x 1050 x 600 mm)

Advantages of CNC Milling in Our Offer

- Repeatability: The closed coordinate system and precise computer control guarantee identical production of each component, making us an ideal partner for serial manufacturing.

- High Efficiency: The automation of the milling process eliminates human errors, significantly speeding up the machining and increasing its overall efficiency.

- Cost Optimisation: The speed and precision of CNC milling help reduce production costs, and once a design is programmed, it can be repeatedly produced without additional expenses.

- Safety: The automated process minimises the risk of malfunctions and accidents, ensuring stable and safe operations.

- Versatility: We perform CNC milling on a variety of materials, adapting to the individual needs of our clients.

Types of CNC Milling in Our Offer

We use CNC milling machines with either vertical or horizontal spindle configurations to optimise the machining process. Our machines are equipped with 3 linear axes (XYZ) and up to two rotary axes (A and C), enabling 5-axis machining – the ability to machine the component from every angle in a single setup. This results in higher accuracy, as each repositioning of the workpiece introduces potential losses in precision.

Application of Our Services

Our specialists are able to determine the most suitable type of milling for each project. We combine CNC milling with our other processes (CNC turning, grinding, etc.) to offer a comprehensive service, ensuring the component is produced according to the specifications and requirements of our clients. This approach efficiently optimises both costs and lead times.